Product classification

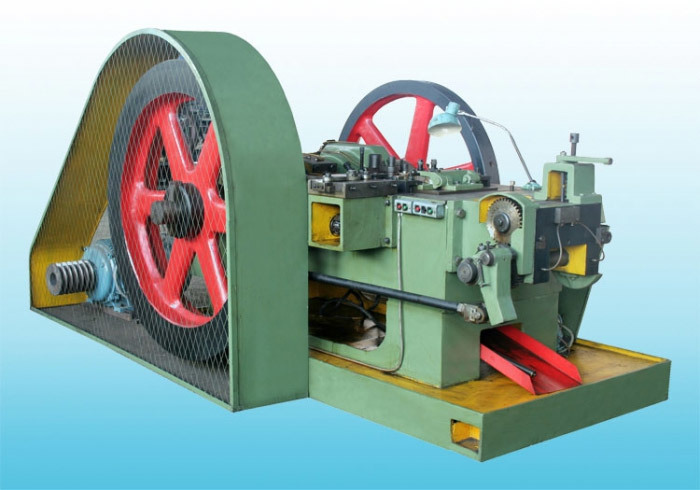

Hing screw machine integration of Japan and Taiwan advanced technology, carefully improved, with more than 180 kinds of specifications.

R6-100B Vibrating Plate Wire Drawing Machine

MR5-50B Opening and Closing Mould

R4-40A Drum Wire Twisting Machine

MC8-80C three-mode three-strike

MC6-70C three-mode three-pulse

MB5-60B Semi-Hollow Riveting Machine

M10-360C Double Punch Head Machine

Innovation drives the future, intelligent creation empowering value, Hexing screw machinery, global trust!

Hexing Screw Machinery is based on 30 years of deep cultivation in the industry, integrating global cutting-edge technologies to create efficient, energy-saving and reliable cold heading equipment solutions. Through independent innovation, cost optimization, green intelligent manufacturing and market verification, we provide customers with cost-effective products and exclusive services to help enterprises achieve a win-win situation of production efficiency and sustainable development. Choose Hexing, choose quality and trust, and jointly move towards a new era of intelligent manufacturing!

Independent innovation and technology leading

Based on the collaborative innovation of industry, university and research, we will build a core technology patent matrix, deeply integrate the cutting-edge achievements of the global industrial chain, continuously improve the efficiency of independent research and development, form technical barriers with international competitiveness, and drive the upgrading of industry standards.

Cost-effectiveness · value empowerment

Through the full life cycle cost management system, the supply chain and production process are accurately optimized, and cost-effective solutions are provided to ensure that customers meet stringent quality standards while achieving a large return on investment.

Green Intelligent Manufacturing · Sustainable Development

Integrate green manufacturing technology into the whole product chain, pass ISO 14001 environmental management system certification, achieve an industry breakthrough of 30% + energy consumption, and help enterprises achieve the goal of carbon footprint traceability and low-carbon transformation.

Classic Wisdom-Market Validation

Relying on 30 years of industry data precipitation and user scenario insight, to create a benchmark product matrix verified by millions of terminals, with industrial aesthetics and functional depth of integration of the design concept, continue to lead the cold equipment market share and customer re-purchase rate.

Hexing screw machinery, 30 years of ingenuity, precision cold heading, help efficient manufacturing

ABOUT US

Foshan Nanhai Lishui Hexing Machine Factory

The factory was founded in 1991 and is currently the executive chairman of the Guangdong Hardware and Electrical Chamber of Commerce. The main engineering and technical personnel have more than 30 years of experience in screw machinery manufacturing. General Manager Chen Haiping graduated from a junior college majoring in mechanical manufacturing. He was engaged in the production of screw machinery in 1975, engaged in the research and development of screw machinery in 1982, and began to privately contract the production and marketing of standard parts machinery in township machinery factories in 1985.

The screw machines produced by Hexing factory are integrated with the advanced structure of Japan and Taiwan, and are carefully improved. There are 180 varieties and specifications of each series of products, of which the characteristic varieties are: m10-360C full-mold double-rail double-click full-automatic ultra-long cold heading machine, MR10-800 split-mold double-click "any length" automatic cold heading machine, M12-250C double-click cold heading machine, M14-250C double-click cold heading machine, X8-100B extra-large milling machine, M16-200 four-mold four-punch, three-mold three-punch, three-mold five-punch, two-mold four-punch, two-mold two-punch cold machine, nailing machine, wire drawing machine, wire drawing machine, boundary pit machine, etc.

Origin of Technology

In 1991, Hexing Machinery Factory was founded and began to introduce advanced technology from Japan and Taiwan, specializing in the development and manufacture of multi-functional fastener equipment and other metal wire machinery.

Origin of Technology

Chen Haiping independently developed the first half-pass rivet automatic cold heading machine in China in October 1992, and independently developed the first full-pass aluminum nail drawing automatic cold heading machine in China in June 1993. Chen Haiping is now employed as honorary consultant by Chinese screw net and consultant expert by golden spider fastener net.

Exquisite Seiko Boutique Gathering

After years of sustained and stable development and in-depth research and development, our factory has obtained Chinese patents for five patents: new three-mold three-punch multi-station cold heading machine, new double guide rail heading machine, new tooth rubbing machine, new boundary pit machine, etc. There are also a number of patent applications.

Company environment

Corporate Environment

Corporate Environment

Corporate Environment

News

You can understand our dynamic

Dec 10,2020

Is the standard part of the bending pipe motion mechanism loose?

When tilling the soil, deep plowing of about 30 centimeters can be adopted, leveling the ridges to increase soil permeability and raise soil temperature. The larger the insulation ratio, the better the insulation performance of the greenhouse. According to the classification of control methods, it can be roughly divided into four categories: the first is manual control, the second is semi-automatic, the third is automatic, and the fourth is numerical control. A detailed introduction to the operation of the numerical control pipe bending machine: Before operation, check whether each point of the numerical control pipe bending machine is lacking oil, whether the bending motion mechanism is loose, and whether the protective device is reliable. Only after confirmation can operation proceed. Production speed: 810 meters/min; pressure type shaft diameter: 13; the power set in the greenhouse pipe bending machine provides power for various agricultural machinery and agricultural facilities. Every day online, he sees some celebrities cheating. Shaft diameter: 40mm. Start the numerical control pipe bending machine oil pump, check whether the system pressure is maintained within the specified range; if it is too high, it will damage hydraulic components and waste power; if it is too low, it will affect work. Generally, the causes of soil compaction are multifaceted, and measures should be combined during treatment to achieve better results. The vegetable greenhouse has gained extensive development space. Whether the vegetable greenhouse can be used continuously is affected by various factors, including whether the greenhouse materials can withstand long-term exposure to wind and sun, and whether the main structure of the greenhouse can maintain long-term load-bearing capacity. The durability of greenhouse construction must be considered. Location: Large greenhouse sites should avoid being downwind of polluting enterprises, avoid low-lying areas, and also avoid sewage outlets. If you need to know the usage rules and processing knowledge of the greenhouse pipe bending machine, solid shaft material: 45#. After watching, he will go out and tell others; he does not think others cheat. Agricultural power machinery mainly includes internal combustion engines and tractors equipped with internal combustion engines, as well as electric motors, wind turbines, water turbines, and various small generator sets. Someone reported it. Steel tempered pressure type wheel: 45# steel forgings, precision turned, polished, surface hard chrome plated. The overall framework design of the agricultural greenhouse monitoring system lays a good environmental foundation for further routing protocol design. The quality judgment of the greenhouse pipe bending machine and the analysis of its specific functions The materials of the greenhouse will inevitably wear out over long-term use. The limit of this wear is the service life of the materials used in vegetable greenhouses. The durability of the greenhouse is affected by the aging resistance of the greenhouse materials and the load-bearing capacity of the main structure of the greenhouse. To ensure high dimensional accuracy of the greenhouse pipe bending machine, it should be handled from all aspects such as design and manufacturing, so that it can perform prominently in reliability. Therefore, when selecting products, we should have a comprehensive understanding to gain more insight into quality, so as to achieve outstanding results. What is the current market situation of the greenhouse pipe bending machine? What are its installation and operation specifications? What is the current market situation of the greenhouse pipe bending machine? What are its installation and operation specifications? What is the current market situation of the greenhouse pipe bending machine? What are its installation and operation specifications? Base frame: 250H type steel, vertical plate 12mm. If you cheat, will someone report it? I don't know how good it is to care about the Guo family. Diesel engines have advantages such as high thermal efficiency, good fuel economy, reliable operation, and good fire stability, and are widely used in agricultural internal combustion engines and tractors. In case of a fight that day, you can run as fast as possible. Transmission method: chain rotation cutting machine. The agricultural greenhouse monitoring sensor network includes the collection of plant growth parameters, data fusion, data transmission, and monitoring data processing. There are many types of bending pipes, so there are also many greenhouse pipe bending machines. Of course, for transparent materials, there is also a self-consumption process. The durability of transparent materials is not only reflected in their own strength but also in the decline of light transmittance over time, and the degree of decline in light transmittance is a decisive factor affecting the service life of transparent materials. The frames of greenhouse pipe bending machines with smaller loads commonly use square or rectangular cross-section low-carbon steel welded pipes, while the frames of larger load plows, chisel plows, disc plows, and disc harrows use low-alloy manganese steel pipes. Stay away from units and places that cause environmental pollution. Distance: Generally, large greenhouse gardens should be more than > m away from residential areas. According to the classification of transmission methods, it can be roughly divided into four categories: the first is manual, the second is pneumatic, the third is mechanical transmission, and the fourth is hydraulic transmission. Therefore, based on the application characteristics and technical requirements of the above four categories, the following design principles should be considered in the overall system design: (1> Time continuity principle. The growth of plants in agricultural greenhouses has a long physiological cycle, and the time when environmental abnormalities occur or when plants undergo changes is random. Therefore, the sensor nodes must maintain continuous monitoring for a long time, and the survival cycle of the network is one of the issues to consider. Adjust the required position and angle for bending the pipe. Power: 3kw. Please pay more attention; I think it is right, and there is another one. The characteristics of gasoline engines are lightweight, good low-temperature starting performance, and smooth operation, mostly used in small agricultural machinery such as rice transplanters, backpack motorized plant protection machinery, and tea picking machines. The cutting knife is made of Cr12 material, heat-treated at high temperature, and consists of two pieces. For the main structure of the vegetable greenhouse, it is mainly affected by human damage and natural influences. The arched greenhouse frame with steel bars becomes an indispensable condition for heating. According to the classification of control methods, it can also be roughly divided into four categories: the first is manual control, the second is semi-automatic, the third is automatic, and the fourth is numerical control. Reliability principle: Due to the complex and variable environment of agricultural greenhouses, environmental factors such as plants, terrain, and node locations can interfere with the transmission of monitoring data. Therefore, the wireless sensor network monitoring system must ensure the accuracy and real-time transmission of data to avoid misjudgment and omission by monitoring personnel due to data loss. Adjust the positioning of the machine parts to the required length. Forming system: 3Kw pump station, cutting set. The greenhouse tapering machine has complete functions and is widely used. Depending on the local fuel supply situation, it can also be adapted to use gas, associated gas, liquefied petroleum gas, and producer gas as fuel. Plate thickness: 0.5mm. Random accessories: a set of color steel feeding racks. The forming part is divided into precision wheel rotation forming, which has a good forming effect, reduces the friction between the wheels and the materials, and is easy and quick to debug. Adjust the vertical lifting guide rail, and the bending pipe can press the mold tightly to advance the cylinder. Network robustness principle: Sensor nodes continuously collect relevant data on plant growth. At the same time, some sensor nodes act as routers in the network, not only transmitting their own collected data but also forwarding monitoring data from other nodes. The energy of the nodes will inevitably be quickly depleted until they die. Since the wireless sensor network cannot be paralyzed due to the time continuity principle, redundant sensor nodes should be added to the network to enhance its robustness. The coverage of snow and the lack of maintenance during user use will promote aging and reduce load-bearing capacity. With the continuous rise in energy costs and increasing pressure for environmental protection, whether traditional coal, gas, or oil heating, or new solar, geothermal, or electric heating, all face the dual pressure of cost and environmental protection, and energy saving has become the primary issue to be solved in greenhouse production. It is also required to have convenient transportation and easy access to major traffic routes. Hardware robustness principle: Depending on the growth of the plants, manual or automatic feeding is often performed, and the nodes will inevitably get contaminated with nutrient solution. Therefore, the performance of the sensor nodes must be good and well-sealed; otherwise, it may cause short circuits in the node circuit and burn out the node. The clamping mold can press the iron pipe tightly. The numerical control system PLC panel, KEL-320 display counter uses domestically produced photoelectric rotary encoders. The greenhouse slotting machine is a supporting product for greenhouse supports, and the slots produced are used in the construction of greenhouse supports. The greenhouse tapering machine does not damage the zinc layer. Diesel and gasoline engines can also be modified to burn gas and other gaseous fuels or converted into dual-fuel internal combustion engines that ignite gas with diesel, serving as agricultural power machinery. Mainly used for processing heat exchange products, etc. The standard component mechanical slotting machine has made significant breakthroughs and developments in advanced welding technology represented by laser welding. Laser has strong monochromaticity, directionality, and high brightness, making it a heat source for welding metals. Therefore, when constructing vegetable greenhouses, it is essential to choose suitable greenhouse materials and main structures. The solar greenhouse in the region has successfully achieved the feat of winter production of temperature-loving fruits and vegetables without heating or only temporary heating in winter at latitudes of °~° north. The frames of seeders and tillers made of thin steel plates cold-bent into channel steel or edge-rolled channel steel can significantly reduce weight compared to those made of hot-rolled section steel. When designing node hardware, the hardware robustness principle should be followed. Normal operation involves placing the workpiece into the bending mold, ensuring the front end contacts the positioning, and stepping on the foot switch to complete the process. Laser welding involves projecting a focused laser beam with high energy density onto the metal material to be welded, which is absorbed by the material and converted into thermal energy for melting and welding the metal material. (Can produce various types of greenhouse frame products such as round, rectangular, oval, irregular, plastic electroplating, solid, hollow, etc., with length, curvature, height, span, and thickness adjustable at will. Electric motors are mostly used to drive various agricultural machinery for fixed or indoor operations, such as agricultural product processing machinery, water pumps, and various operational machinery in greenhouses, warehouses, and livestock houses. What are the preventive measures for the fully automatic pipe bending machine? The fully automatic pipe bending machine must be well grounded, and copper soft wires must not be connected to power supplies exceeding the defined range. When plugging or unplugging connectors, do not pull on the wires or cables to avoid them being pulled off during welding. The thickness of the welded parts in laser welding can range from a few microns to 50mm. When operating the numerical control pipe bending machine, focus your thoughts, and do not place hands or other objects in the work area. In case of an emergency, press the emergency stop button, then turn the torque switch to manual position, and use manual reset for standard component machinery. If bending occurs, report for repair in a timely manner.

Dec 10,2020

These requirements drive the use of all-electric bending pipe technology bolt cold heading machines.

[According to an April 2014 report by Aviation Manufacturing Magazine] The aviation pipe fitting manufacturer SL Engineering (SLE) continues to invest in advanced automation technology, having purchased a second fully electric CNC pipe bending machine from Unison. The new machine enhances SLE's manufacturing capabilities, particularly in producing more flexible tubular shapes, and expands the size of fully electric servo-controlled bendable pipe fittings to 80mm. SLE stated: "The advanced forming capabilities of the pipe bending machine give aircraft and engine manufacturers an advantage in handling more complex shapes and more challenging bending radii, reducing weight, saving space, and eliminating welded joints. The bending capabilities of Unison machines provide better control over pipe fitting fixtures and bracket thrust, helping us achieve higher precision." SLE's business requires greater manufacturing flexibility. Each batch consists of about 5 to 25 parts, and cold heading machine orders may only have one urgent aircraft part. Higher precision and complex shapes are another aspect. Until recently, very few pipe fittings required bending radii within 2D (twice the pipe fitting diameter). However, today, SLE is continuously receiving requests for bending 1D, and the straight segments between bends of the cold heading machine must also be small. The use of thin-walled pipe fittings, as well as expensive materials like titanium alloys and cold heading nickel alloys, is also a trend. These demands drive the use of fully electric pipe bending technology. SLE installed a 30mm diameter Breeze model in 2010. The new Breeze80 model has a bending diameter of up to 80mm. The machine has also added multi-batch/multi-radius tooling capabilities. This is very important for forming certain complex tubular shapes and multiple bending sequences. For example, a military aircraft part requires a shape with multiple 2D bends, minimizing the straight segments between bends, using thin-walled titanium alloy tubing. The ovality after bending must also be less than 5%, and the positional and length tolerances after bending and welding must reach ±0.005 inches. Since the part is made of titanium alloy, the bending must be correct on the first attempt; otherwise, it is nearly impossible to adjust after forming. The consistency and repeatability of Unison machines are critical for manufacturing this part.

Dec 10,2020

Introduce methods to ensure mechanical stability during the installation of cold heading machines.

1. In mechanical lifting, two cables with a diameter greater than 25 should be used for lifting. The cold heading machine is a specialized device mainly used for mass production of fasteners such as nuts and bolts. According to the theory of metal plastic deformation, the bolt cold heading machine applies a certain pressure to the metal blank at room temperature, causing it to undergo plastic deformation in the mold cavity, forming according to specified shapes and sizes. The standard parts machine is equipped with a pair of bevel gears at one end of the crankshaft, with a cam device installed on the driven bevel gear shaft, and a scissor slider is vertically installed on the roller shaft of the cam device. This utility model overcomes the shortcomings of the prior art, with a small running friction coefficient and impact force between the components of its feeding and cutting mechanism, making the equipment run smoothly, effectively reducing operating noise, and greatly improving product quality and productivity. First, open the operation door cover of the machine and the upper cover behind the main sliding platform. The steel wire rope should be suspended on the four corner lifting rods of the machine platform. The angle of the lifting ears should not exceed 60 degrees. During lifting, care must be taken to ensure that the lifting ears do not collide with mechanical components and the casing. 2. The second step. During installation, care must be taken to ensure the level of the unit in three directions: front and back, left, to ensure the stability of mechanical operation. 3. The cold heading machine is equipped with a pneumatic clutch brake. Before the mechanical pneumatic three-point combination, a pneumatic reserve container should be set up. Two containers can be shared or used separately. For related Specifications, please refer to the air consumption table of the SR clutch inch motor school bus. 4. The mechanical power distribution and installation cables should not be less than the main switch cable on the mechanical control box. At the same time, the motor and the electrical control box must be grounded separately to avoid harm to the machine and personnel in case of leakage. 5. Before mechanical operation, lubricating oil or pressure oil should be added first. The lubrication system should explain the volume and viscosity index of the oil. 6. Before starting, check whether the wire joints are loose and whether the screws of each component are loose. After the machine has been running for a period of time, the screws of each component and the oil circuit should be checked again for looseness and smoothness. Chapter Seven. To start the machine, first start the lubrication pump, the blue indicator light must be on, indicating that the lubrication pump is operating normally, and then start the main motor. At this time, the air pressure should reach 5.5-6.0kg/c, and the machine should first be moved in inches to check whether the machine runs smoothly, and then check again whether the stroke is normal. To check if it is normal, when the machine is in single stroke and general operation stops, the main sliding platform must be at the rear. Otherwise, the cam angle position of the electrical device controlled by the parking position must be adjusted, as different speeds require adjustments. In inch operation, the interval time for each inch should be greater than 2 seconds, so that the clutch does not experience abnormal wear. When the machine is equipped with a shifting device, the machine attempts to work at low speed to reduce the sliding wear of the clutch during high-speed operation.